|

|

|

Impact Testing

|

|

|

|

Test methodology

|

|

|

|

The objective of this test was to find out how tough each blade material was.

|

|

|

|

There is no set quantifiable variable to measure the toughness of a woodworking

blade. Intuitively, a woodworker would state that a material with superior impact

strength will maintain cut quality for a longer period of time.

|

|

|

|

It must also be recognized that an alloy may perform differently at different bevel

angles.

|

|

|

|

|

|

Our impact test was designed to emulate the normal chopping action of a chisel.

The wood was clamped in a jig, and the blade was set to chop ⅛" of material. The

blade was held with the cutting edge against the wood and parallel to the end of

the piece. A known weight was dropped on the end of the blade from a height of 300mm.

(This height was chosen because after impact it resembled a typical chop that a

woodworker would make.) After each chop the depth of cut into the wood was recorded,

and the blade was examined for any edge failure. We measured the damage to the blade

after a set number of impacts.

There were three variables controlled in the impact test that were maintained throughout

the tests: impact energy, the type of wood being cut and the number of impacts.

The impact energy was defined by a mass of 2.9 kg falling from a height of 300mm.

The resulting impact energy was 8.5 J. The material being cut was red oak, chosen

because it is a common hard wood and it scores in the mid-range of commonly used

woods on the Janka Hardness scale.

|

|

|

|

|

The impact testing was performed at four micro-bevel angles: 20°, 25°, 30° and 35°.

The results were measured and recorded after one and three impacts. Each test was

performed three times (six total tests) to see if consistent results were achieved.

|

|

|

|

Test results

|

|

|

|

Each blade tested was scored based on the amount of edge failure. For presentation

purposes, the top-scoring material was assigned a score of 10 and the lowest-scoring

material was assigned a score of 1. Intermediate performing materials were assigned

linear scores. (Note that this does not mean that the top metal scored 10 times

better than the lowest metal.)

|

|

|

|

|

|

|

|

|

O1: 6 chops

|

|

A2: 6 chops

|

|

|

|

|

While the metals were assigned code letters for testing, we have indicated O1, A2,

M4 and PM-V11.

|

|

|

|

Material

|

Impact Test Score

|

|

PM-V11

|

10

|

|

W

|

9

|

|

Y-1

|

7

|

|

N1

|

6

|

|

M4

|

6

|

|

Z-1

|

6

|

|

X

|

5

|

|

N-2

|

4

|

|

R-1

|

4

|

|

S

|

4

|

|

Q

|

3

|

|

R-2

|

3

|

|

Y-2

|

3

|

|

T-1

|

2

|

|

V-1

|

2

|

|

V-2

|

2

|

|

Z-2

|

2

|

|

A2

|

1.5

|

|

P

|

1.5

|

|

T-2

|

1

|

|

O1

|

1

|

|

|

|

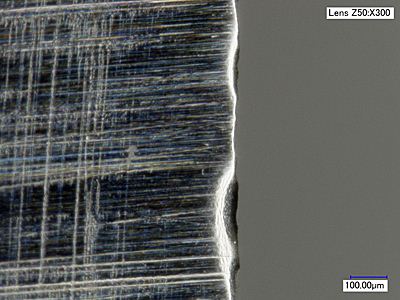

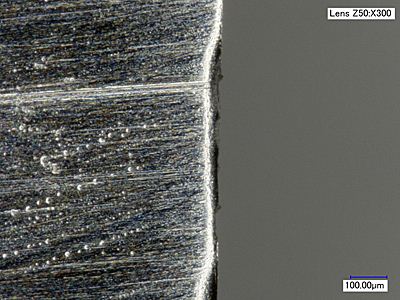

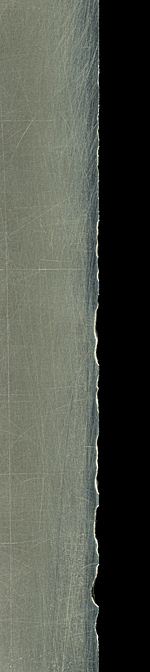

Sample Impact Test Images

|

|

|

|

|

|

|

|

|

|

|

O1

|

|

A2

|

|

M4

|

|

PM-V11

|

|

|

|

|